Sublimation Paper in Pakistan – 2026 Buyer’s Guide

Sublimation printing has become one of the fastest-growing digital printing technologies in Pakistan, especially within the sportswear, fashionwear, promotional merchandise, and home textile industries. Cities such as Sialkot, Karachi, Faisalabad, and Lahore now rely heavily on sublimation paper and sublimation ink to produce high-quality prints for export markets including the USA, UK, Germany, and the Middle East.

As demand rises, customers often struggle with selecting the right sublimation paper, understanding GSM differences, comparing sublimation paper prices in Pakistan, choosing the best sublimation ink, and fixing quality issues such as dull colors, ghosting, ink bleeding, and moisture problems.

This 2026 Buyer’s Guide provides a complete, technical, and professional overview of sublimation paper, sublimation ink, heat press settings, and printer compatibility for both beginners and advanced users.

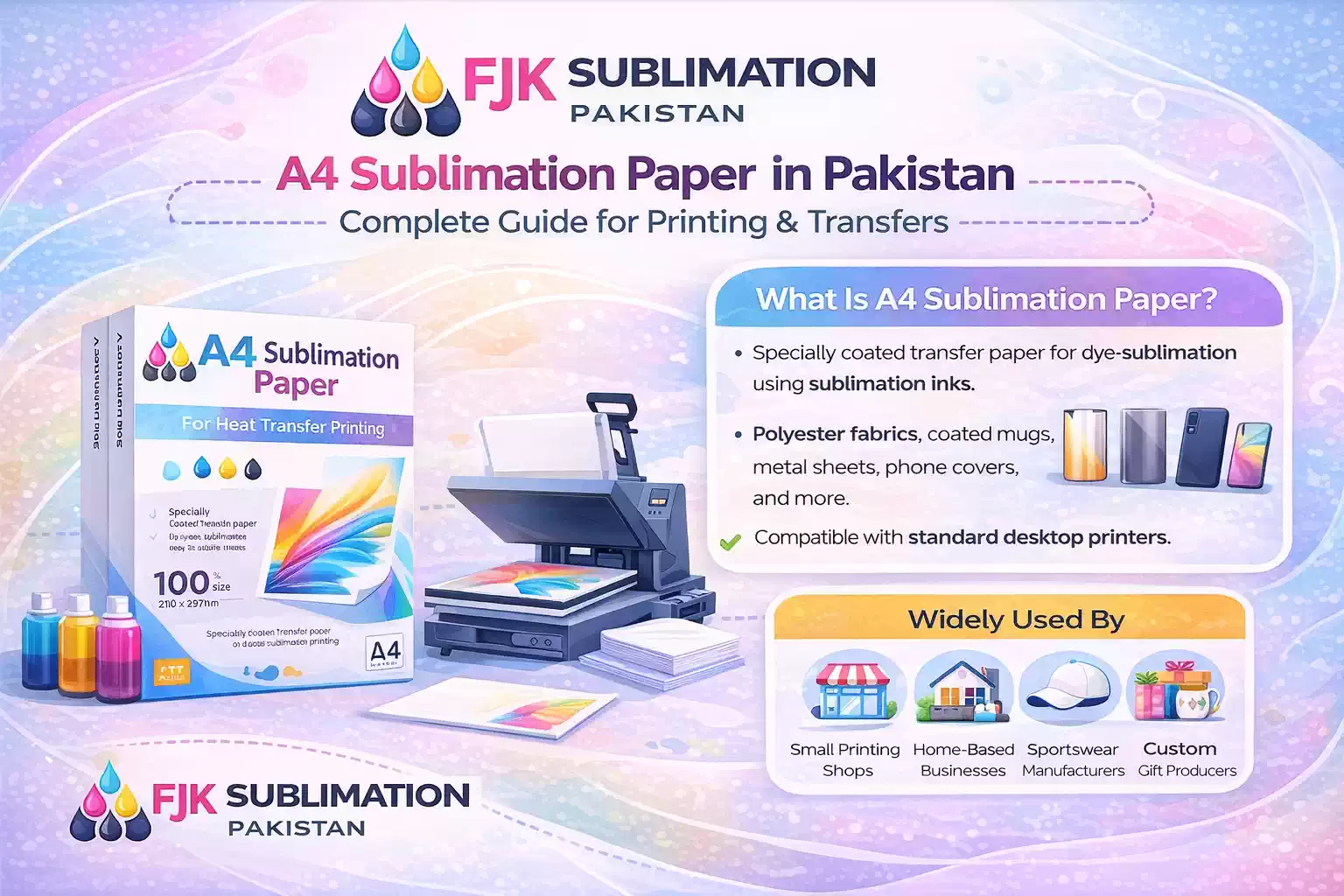

What Is Sublimation Paper and How It Works

Sublimation paper is a special transfer medium coated with a polymer layer designed to hold sublimation ink until it is transferred onto a polyester surface. During heat press application:

Ink turns into gas

Gas bonds with polyester molecules

Design becomes permanent

Colors appear vibrant, durable, and wash-resistant

The paper’s performance depends on:

GSM (70, 80, 90, 100, 120gsm)

Coating quality

Drying speed (Fast Dry vs. Standard Dry)

Ink absorption and release rate

Heat press pressure and temperature

Higher-quality papers produce sharp edges, accurate color reproduction, and minimal ink bleeding.

Sublimation Paper Price in Pakistan (2026 Updated Guide)

Prices vary depending on GSM, size, roll width, brand, and coating technology. The following ranges are commonly seen in Pakistan:

Prices vary depending on supplier, brand, and exchange rate fluctuations (CNY, USD, TRY).

Roll Sizes

| Roll | GSM | Price Range (PKR) | Usage |

|---|---|---|---|

| 24 inch | 70/80gsm | 18,000–28,000 | Sportswear panels |

| 36 inch | 70/80gsm | 24,000–34,000 | Large fabric printing |

| 44 inch | 70/80gsm | 36,000–55,000 | Industrial production |

| 63 inch | 70gsm | 60,000–95,000 | Bulk exports |

Sheet Sizes

| Size | GSM | Price Range (PKR) | Usage |

|---|---|---|---|

| 8.5×11 | 70–100gsm | 450–850 | Mugs, keychains |

| A3 | 70–100gsm | 1,100–1,700 | T-shirts, panels |

| 11×17 | 70–100gsm | 950–1,500 | Jerseys, sleeves |

| 13×19 | 100gsm | 1,500–2,200 | Sportswear panels |

Types of Sublimation Paper Used in Pakistan

1. Standard Dry Sublimation Paper

Suitable for Epson L-series printers

Used for mugs, t-shirts, mobile covers

More affordable but slightly slower drying

2. Fast Dry Sublimation Paper

Instant absorption

Ideal for high-speed production

Best choice for sportswear factories

3. High-Release Sublimation Paper

Releases 95%+ ink

Produces deeper blacks and vibrant reds

Recommended for jerseys, leggings, hoodies, flags

4. Sticky Sublimation Paper (Tacky Paper)

Used for jersey printing (to prevent shifting)

Prevents ghosting

Commonly used in Sialkot sportswear industry

5. Roll Sublimation Paper

Industrial printing using Epson I3200 or 4720 heads

Used for bulk sportswear and bedsheets

Sublimation Ink in Pakistan – Best Brands Reviewed (2025-26)

Pakistani printers commonly use the following international sublimation ink brands:

1. Sublinova Smart (Korea)

Known for color accuracy and stability

Best for Epson printers

Widely used in Sialkot factories

Price range: PKR 6,500–8,500 per liter

2. Luster Innova HD Sublimation Ink (Turkey)

High-density color output

Smooth flow, reduced nozzle clogging

Excellent for neon shades and deep blacks

Price range: PKR 6,000–7,500 per liter

3. InkTec SubliNova G7

Very stable at high-speed printing

Ideal for I3200 printheads

Price range: PKR 6,500–7,800 per liter

4. SubliX Sublimation Ink

Affordable alternative

Good for beginners / home businesses

5. G-Ink (Thai Origin)

Strong color intensity

Often used in mid-size setups

6. Chinese OEM Inks

Lowest cost

Best for low-volume printing

Choosing the Right GSM for Sublimation Paper

70gsm

Best for sportswear

Fast drying

Low ink usage

High-speed printing compatibility

80gsm

Stronger and smoother

Suitable for flags, leggings, hoodies

90–100gsm

Thick and stable

Best for mugs, plates, keychains, MDF

120gsm

Specialty use, heavy coating

Sublimation T-Shirt Printing Cost in Pakistan (2026 Estimate)

| Component | Cost Estimate (PKR) |

|---|---|

| Paper (A3 sheet) | 25–40 |

| Ink usage | 35–60 |

| Heat press electricity | 5–10 |

| Labor | 20–40 |

| Total Cost per Shirt | 85–150 PKR |

Export-quality sportswear may cost more due to:

Tacky paper requirement

High-density inks

Pre-press treatment

Multiple panel printing

Choosing the Best Sublimation Paper for Sportswear — Expert Guidance

For sportswear manufacturers (especially Sialkot exporters), the following specifications are crucial:

Use 70gsm fast-dry tacky paper

Use I3200/4720 printers for accurate color

Maintain room humidity 45–60%

Use professional ICC profiles

Use Luster Innova HD or Sublinova Smart inks for neon and deep shades

This ensures stable blacks, accurate team colors, and consistent results during bulk orders.

Comparison: Sublimation Paper Rolls vs. Sheets

Rolls

Higher production efficiency

Less paper waste

Recommended for factories

Sheets

Best for small businesses

Easy handling

Low initial cost

How Humidity Affects Sublimation Paper Performance

Humidity directly impacts drying time and print sharpness.

Low Humidity (<35%)

Ink dries too fast

Leads to grainy prints

High Humidity (>60%)

Paper becomes wavy

Ink bleeding and ghosting occur

Maintain climate control for consistent production quality.

Common Sublimation Printing Problems and Solutions

1. Dull Colors

Increase temperature

Use high-release paper

Check ICC profile

2. Ghosting

Switch to tacky paper

Increase pressure

3. Blurry Edges

Reduce ink load

Switch to thicker GSM

4. Banding

Clean nozzles

Lower print speed

5. Yellowish Prints

Incorrect press time

Substandard ink

Recommended Sublimation Printer Settings

Epson L805 / L1800

Best for small businesses

Standard or fast-dry paper

Epson XP600 / I3200 / 4720

Best for industrial printing

70gsm tacky paper recommended

Final Recommendations (Based on 2026 Industry Data)

For Sportswear Exporters

Use:

70gsm Tacky Fast-Dry Paper

Luster Innova HD or Sublinova Smart

For Local T-Shirt Printers

Use:

100gsm standard sheet paper

Chinese or Sublinova ink

For Mug Printers

Use:

100gsm premium sheet paper

High-density ink